Waste Treatment Solution Through Carbonization Furnace Technology In The Bangladesh.

Key Services

Hazardous organic and synthetic organic waste managemet

Turn key services for the project

Maintenace and periodical Services

Carbonization Furnace Technology

K2 Technologies of Japan developed the Carbonization Furnace Technology.

Carbon Furnace Technology operates under the principle of ‘Pyrolysis’ through ‘Destructive Distillation’.

Pyrolysis is a thermochemical decomposition of organic material at elevated temperatures in the absence of oxygen. It involves the simultaneous change of chemical composition and physical phase, and is irreversible.

Pyrolysis is the thermal degradation of organic materials, using an indirect source of heat at 750-1,200deg C in the absence of oxygen, to produce a synthesis gas, leaving behind a carbon char.

Pyrolysis is mostly for organic materials or Biomass.

Destructive Distillation is the decomposition of a solid by heating it in a closed container and collecting the volatile constituents given off. It is the process in which a solid material is heated at high temperature out of contact with air to make coke, coal, tar or charcoal. It is called ‘destructive’ because the chemical composition of the end product is distinctly different from that of the input material.

Difference between Decomposition and Combustion/Carbonization

Thermal Decomposition | Combustion | Pyrolysis |

means that the synthesis gas of various components such as volatile components and decomposition products is released by heating the organic substance in the oxygen-free (low oxygen) state, leaving solid matter of only carbon content and carbide. | is an oxidation reaction of carbon and oxygen in organic matter to and oxygen in organic matter to generate carbon dioxide, flame and heat. | is a thermochemical decomposition or organic material at elevated temperatures in the absence of oxygen. It involves the simultaneous change of chemical composition and Physical phase, and is irreversible. |

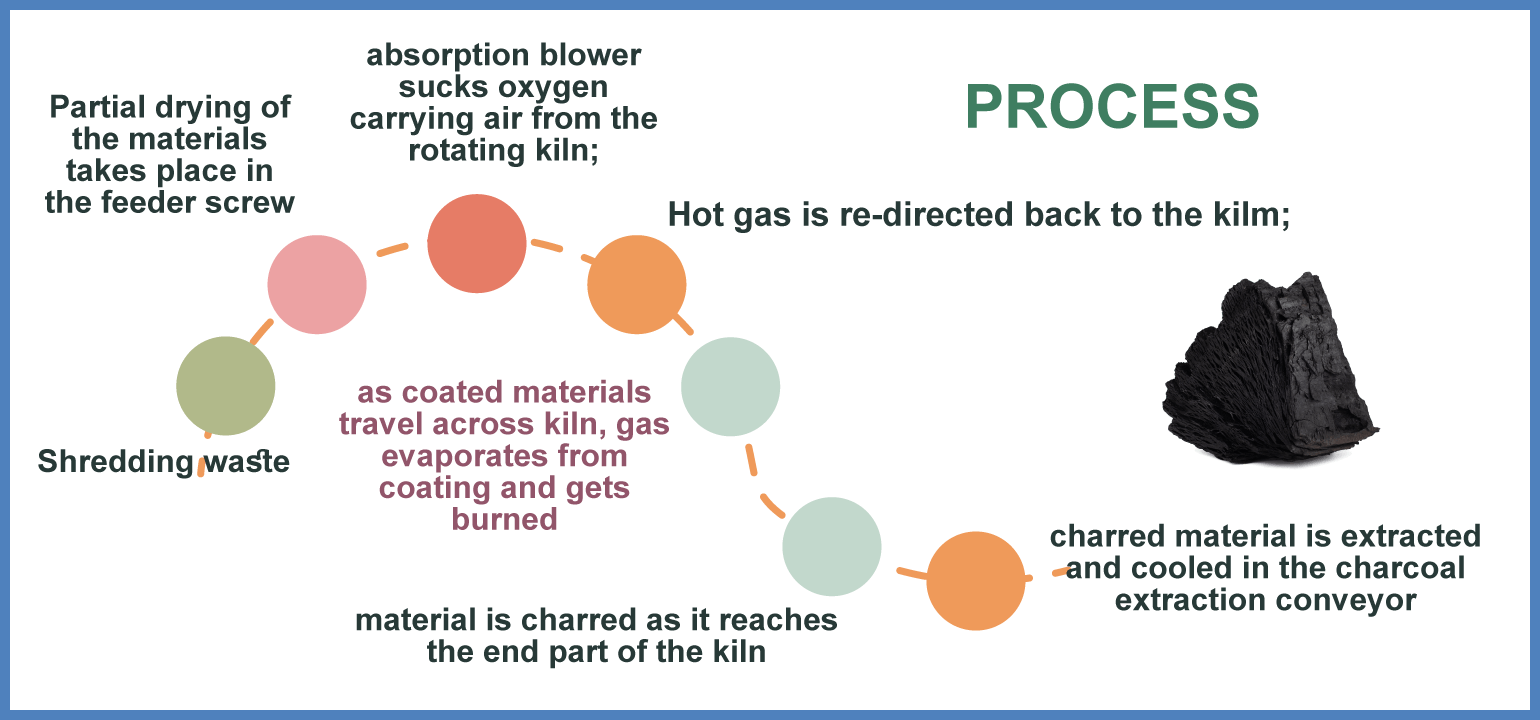

Description of the Carbonization Process

- Extracting the exhaust gas (emission);

- Hot gas exits from the secondary combustion chamber;

- Passes through the heat exchanger;

- Passes through the cyclone dust collector;

- Expelled to the atmosphere by the exhaust blower in the chimney;

- The chimney is equipped with a CEMS

Continuous Emission Monitoring System- an equipment necessary for the determination of a gas or particular matter concentration or emission rate using pollutant analyzer measurements and a conversion equation, graph, or computer program to produce results in units of applicable emission.

What makes Carbonization Processing Technology Unique?

- The K2 Binder

- The ‘K2 Binder’ is a natural inorganic compound (powder form) used to coat the surface of the waste materials of both organic or inorganic feedstock that will be processed by the Carbonizing Machine.

- The ‘K2 Binder’ is responsible for:

- generation of ‘distillation gas’ that is ‘burned’ during the carbonization process; the coated feedstock is not burned but the ‘distillation gas’ do;

- The product of combustion produces more heat thus providing sustainable heat source;

- Capturing “dioxin & furan” prevents the formation of chlorine-based chemical, wherein K2 Binder eliminates ‘dioxin & furan’ emissions;

- The production of activated charcoal (biochar), Fertilizers, Seasonings, Preservatives etc. Components present in color pigments are suppressed by potassium.

- By using a binder, carbonization treatment in in aerobic environment is enabled, and at the same time, chlorine compounds that cause dioxin generation are immobilized.

- In addition, heavy metals contained in waste are oxidized into carbonization process and become detoxified.

- The carbonization of plastics, toxic medical waste and other organic material is made possible.

- Other uses of Biochar: Ink Production, Soundproofing & Insulation Materials, Fire Proof Boards, Battery Rods, Poultry Bedding.

Black Gold

Scientists at the American Chemical Society meeting presented the results of a controlled study of black glod agriculture. And they found that fertilizing with charcoal produced more crops and captured carbo from the air, right out of the CO2. So the practice could also combat global warming.

Poor quality soil. It’s a problem for farmers around the world. Dirt stripped of nutrients by years of over-farming and chemical fertilizers. There’s new evidence that an old farming practice traced back at least 1,500 years to tribes in the Amazon basin can give new life to nutrient-poor dirt. It’s called” black gold agriculture.” The idea is really simple. You add charcoal from burned organic matter to the soil and the dirt holds on to nutrients and produces lots more crops.

Proprietary Enzme Binder

Scientists at the American Chemical Society meeting presented the results of a controlled study of black glod agriculture. And they found that fertilizing with charcoal produced more crops and captured carbo from the air, right out of the CO2. So the practice could also combat global warming.

Conventional Charcoal kilns, drying of feedstock to 15% moisture content is necessary before carbonization, the K2 Process is able to carbonize wet waste e.g. organic waste matter of up to 90% moisture content.

Wet Organic Waste Matter

Conversion into carbon under aerobic condition is made possible with the use of proprietary enzyme binder.

Charcoal Produced by the Binder

Poisonous Dioxins

Solidify or carbonize mixed wet Municipal Waste for landfill disposal.

Poisonous dioxins emitted when plastics are processed are eliminated without huge capital expenditure of plant and equipment normally included in Municipal Waste Treatment Plant.

Toxic medical wastes in plastic disposal bags is carbonized for safe disposal without handling.

Entire process is completed within 20 minutes instead of 8 to 12 hours. Process time depends on moisture content of raw materials.

Greenhouse Gas Effect

When organic material such as food scraps and green waste is put in landfill, it is generally compacted down and covered. This removes the oxygen and causes it to breack down in as anaerobic process. Eventually this releases methane, a greenhouse gas that is 21 times more potent than carbon dixide. The implications gor global warming and climate change are enormous. Methane is also a flammable gas that can become dangerous if allowed to build up in concentratiion.

The Solution for Bangladesh

Carbon Furnace K2 Technology, Japan, a new environment friendly and safe technolgy: 1) An Alternative Solution to the Landfill System:

- An Alternative Solution to the Landfill System:

Benefits:

* Soils Enhance

* Makes plant roots sturdier

* Resistant to pest & diseases

* Neutralizer pH Condition